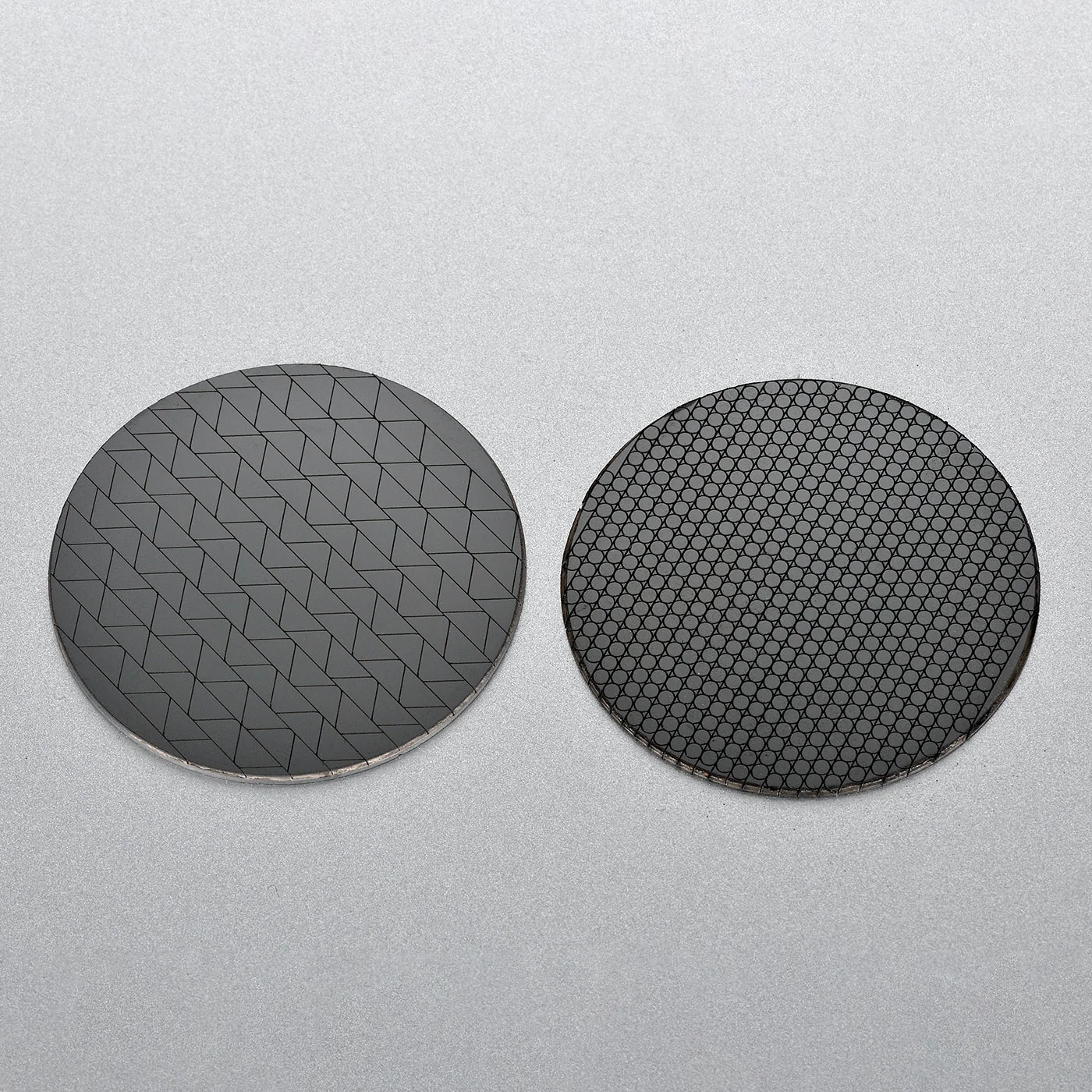

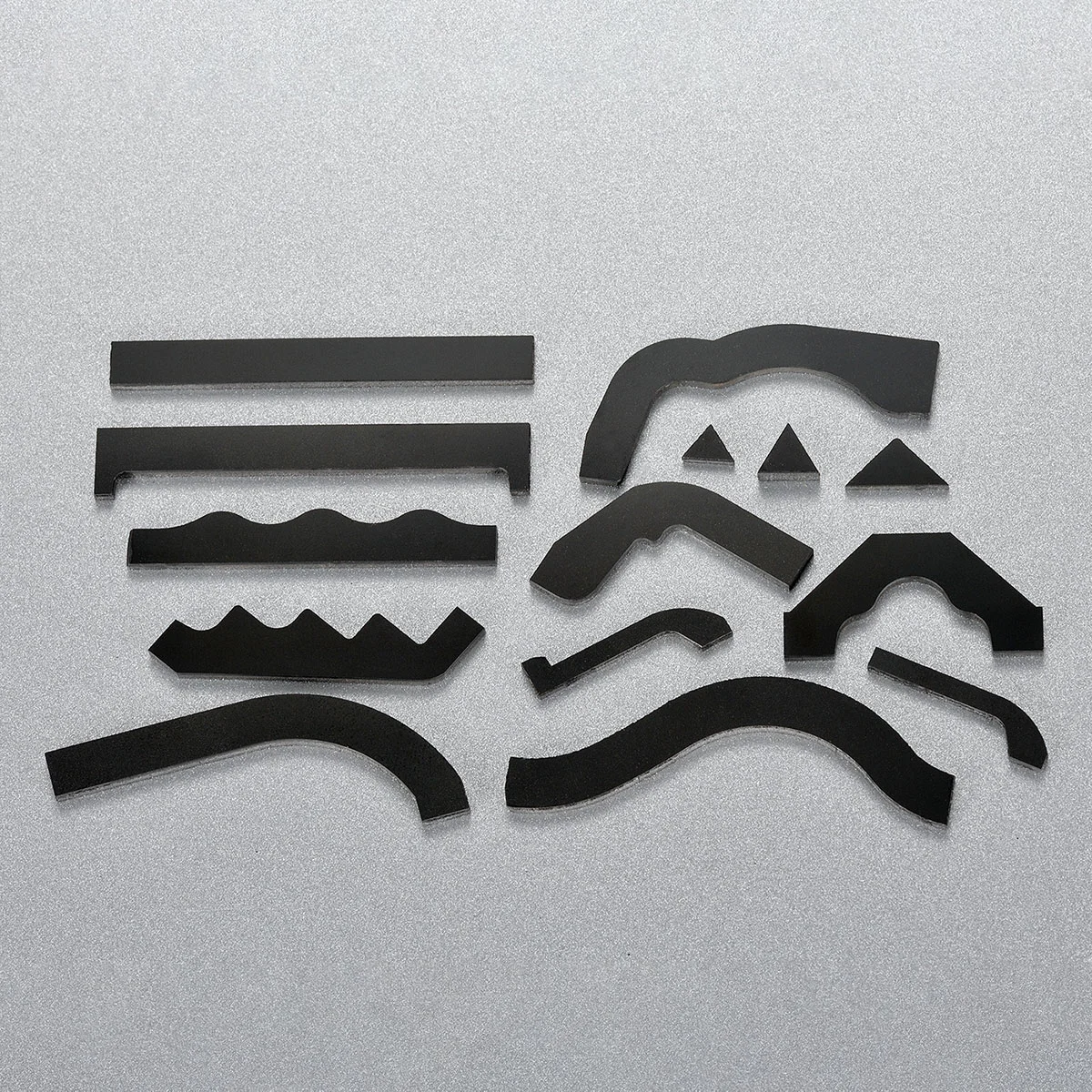

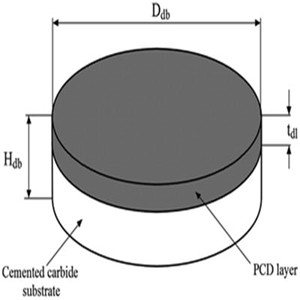

Product structure diagram

Specifications and performance

| Specification model | Particle size | Characteristic | Application field |

| ZYD510 | super coarse particles and mixture particle size | It is an ultra-high hardness and extremely high wear resistance with ultra high toughness super coarse mixture particle size material. It is used in the field of difficult processing and harsh processing environment. It is a special requirement and application. material. | Used in the processing of ultra-wear-resistant industries such as stone, woodworking, non-ferrous metals, silicon aluminum alloys, carbon fiber composite materials, tungsten carbide, high-strength cast iron and dual-color metal materials. |

| ZYD302 | coarse particles and mixture particle size | Ultra-high wear resistance and toughness, heat resistance and thermal stability, excellent conductive processing properties and machining property. | Widely used in the processing of woodworking (solid wood, multi-layer forest board, medium density board, etc.), stone, non-ferrous metals, hardened rubber, graphite, tungsten carbide, ceramics, metal matrix composites, high-strength carbon fiber composites, etc. |

| ZYD010 | medium grain size with strong applicability | Strong diamond bonding, excellent wear resistance and toughness, good electrical discharge machining and machining property | Widely used in the processing of a variety of materials, especially for the processing of non-ferrous metals, including aluminum, aluminum alloys, copper, copper alloys, fiber reinforced composite materials, woodworking (solid wood, multi-layer boards, medium density board, etc.) and electronic materials, Molds and tool materials of choice for new and unknown machining applications. |

| ZYD005 | fine grain size | Excellent toughness and sharpness, excellent electrical conductivity and machinability | Used in the electronic materials, non-ferrous metals fashioning, low, medium and high silicon content aluminum alloys, electronic circuit boards and so on high-speed processing,Recommended for the preparation of complex tools |

| ZYD001 | ultrafine particle size | High toughness and high wear resistance, excellent electrical conductivity and processing properties, can produce sharp and high precision cutting edge | Mainly used in high-speed, high-precision, high-gloss processing fields of various non-ferrous metals, titanium, titanium alloys, liquid crystal displays, high-hardness brittle composite materials, electronic materials and plastics. |