Get a Quote

We will contact you within 24 hours.

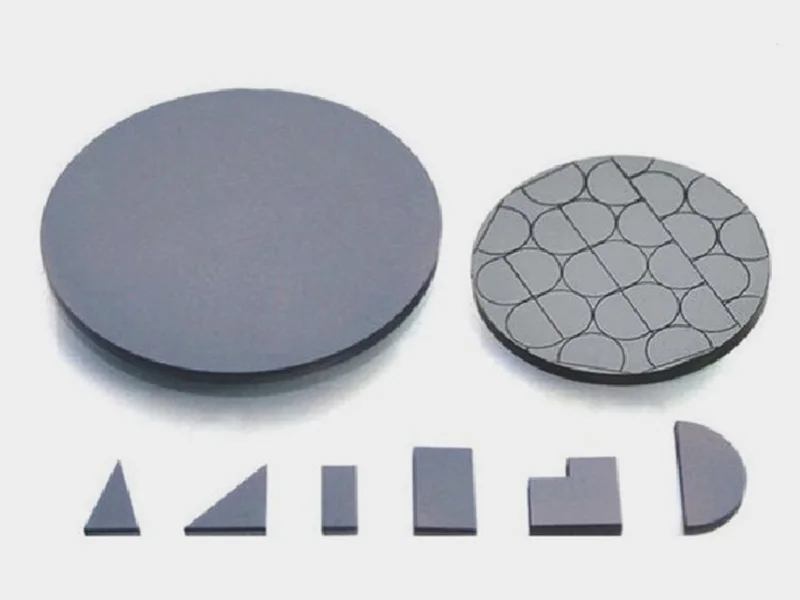

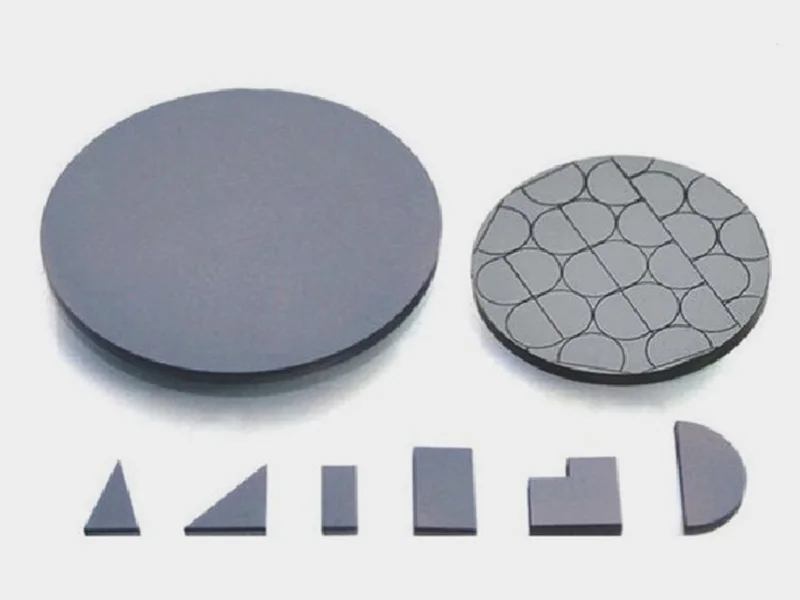

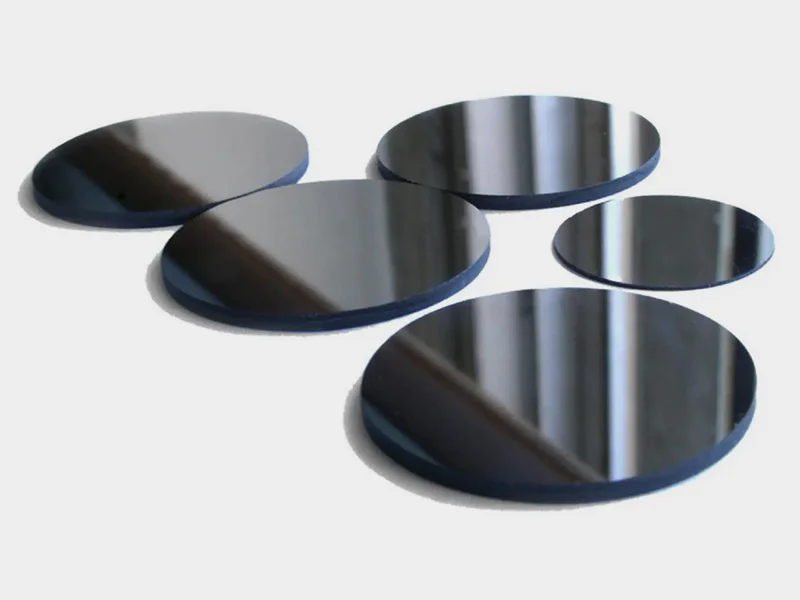

Polycrystalline Cubic Boron Nitride (PCBN)

-The Choice for Ferrous Metalwork

Cubic Boron Nitride Composite Sheet (PCBN) for processing ferrous materials

Polycystalline Cubic Boron Nitride Composite Sheet (PCBN) has high hardness and wear resistance. The hardness of PCBN is generally HV3000-5000, and the heat resistance can reach 1400-1500 ℃. It also has good red hardness and high anti oxidation ability. Polycystalline PCBN does not undergo oxidation at 1000 ℃ and does not undergo chemical reactions with iron-based materials at 1200-1300 ℃. The thermal conductivity of tools made of PCBN is lower than that of diamond but much higher than that of hard alloy, which is beneficial for improving the machining accuracy and surface smoothness of workpieces. The friction coefficient of tools made of PCBN for processing different materials is between 0.1 and 0.3, which is much lower than that of hard alloy (0.4 to 0.6), making it less likely for CBN tools to form retention layers or chip deposits during cutting.

| Compare | PCBN | Carbides |

| Hardness | 4,000~5,000HV (rnd.) | 1,500~2,500HV |

| Thermal Conductivity | 40~60w/m·K | 30~200W/m·K |

| Friction Coefficient | 0.05~0.1 | 0.2~0.4 |

| Thermal Expansion Coefficient (TEC) | 2.0E-6~3.0E μm/m·K | 4.5E-6~7E-6μm/m·K |

| Affinity | LOW (rel.) | HIGH |

Micron-sized CBN particles. Excellent Fracture Toughness. Excellent Fracture Wear Resistance.

Fine grain with high toughness. Excellent chemical resistance. Good wear resistance and impact resistance.

| Specification model | ZYN-90 | ZYN-80 | ZYN-60 |

| CBN content | 90% | 80% | 60% |

| CBN granularity | 4um | 3um | 3um |

| Binding agent | Wolfram, cobalt, aluminum, titanium nitride | Titanium based binder,titanium carbonitride | Titanium carbide, titanium nitride |

| Structural features | For general-purpose materials, micron-sized CBN particles have excellent fracture toughness and wear resistance. | Good wear resistance and impact resistance, excellent chemical resistance, fine grain size and high toughness | CBN has small particle size, low concentration, good wear resistance, impact resistance and chemical stability. |

| Application field | Suitable for processing all types of materials, continuous and moderate interrupted cutting, cast iron, hardened steel, both toughness and high wear resistance | Suitable for processing all kinds of powder metallurgy materials, suitable for high-speed and high-speed processing of hardened steel with hardness greater than HRC45 (suitable for continuous, intermittent processing, and coarse and fine machining) | Good continuous edge machining for ferrous materials, high tool life and high workpiece quality, suitable for all kinds of hard cutting, and excellent for continuous and medium interrupted cutting. Recommended for Processing hardened steel |

High speed steel, Hardened steel, Cast Iron, Hard cast iron, Heat resistant alloy steel, Powder metallurgy, High cobalt chromium molybdenum corrosion resistant alloy

Moresuperhard PCBN is ideal for tools used for the machining of Powder Metallurgy